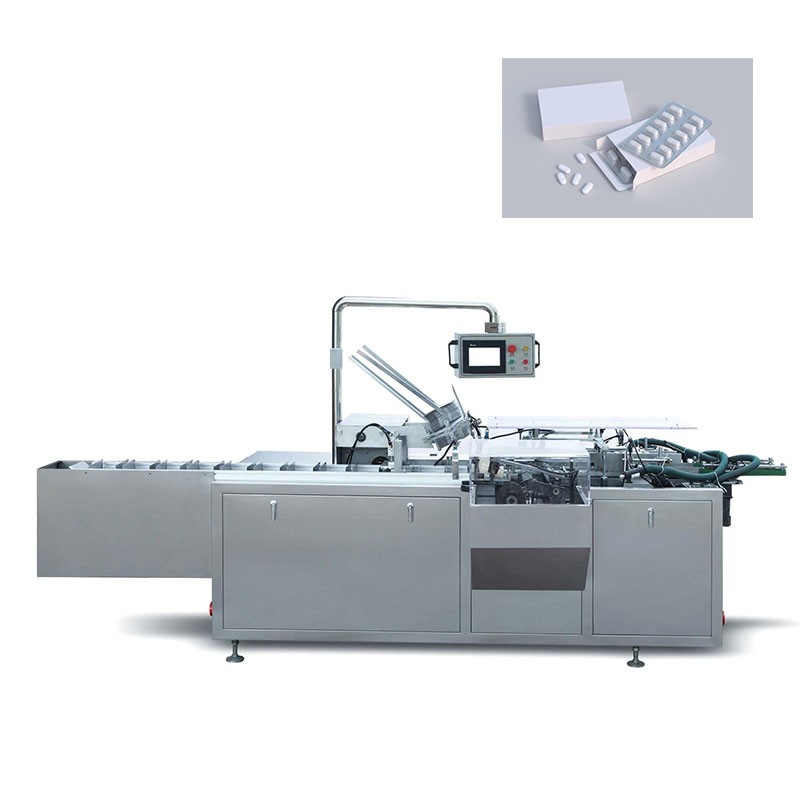

Blister Medicine Automatic Cartoning Machine Factory

Model: KXZ-100A

Our pharmaceutical cartoning equipment blister cartoning machine is extensively utilized in pharmaceuticals for automating the process of placing blister packs into boxes.

- Packing speed:30-90cartons/min

- Application Box Size:L(70-220)mm×W(14-90)mm×H(14-65)mm

- Cardboard Material:300-450g/㎡

- Instruction size (Unfold):(80-150) x (90-170)mm

- Technical Parameter

- Electrical Parameter

- Application Samples

| Model | KXZ-100A |

| Packing speed | 30-90cartons/min |

| Size of package | L(70-220)mm×W(14-90)mm×H(14-65)mm |

| Cardboard material | 250-350g/㎡ |

| Instruction material | 60-70g/㎡ |

| Instruction size (Unfold) | (80-150) x (90-170)mm |

| Instruction size (Fold) | (1-4) Fold |

| Motor power | 1.5kw |

| Power supply | 220V 50HZ |

| Minimum Air pressure | 0.6Mpa |

| Air consumption | 120-160L/min |

| Maximum noise | 80dB |

| Overall dimension | L3100mm×W1100mm×H1900mm |

| Weight | 1500Kg |

| PLC | CPIE-N30DT-D/Omron |

| PLC Extened Module | CPIE-C1F11/Omron |

| Touch Screen | NB7W-TW00B/Omron |

| Sensor | E3Z-D61/Sick |

| Frequency | 3G3JZ-A4015/Omron |

| Relay | MY2 NJ24V/Omron |

| Button | XB2/Schneider |

| Emergency Stop | ZB2 BC4D/Schneider |

| Electromagnetic Valve | 4V210-08/Airtac |

| Pressure Regulator Valve | BFR-2000/Airtac |

| Proximity Switch | TL-Q5MC1/Omron |

| AC contactor | LC1E3210M5N/Schneider |

| Air switch | 3P32A 1P6A/Schneider |

| Vaccum Sounder | ABM20-C/SMC |

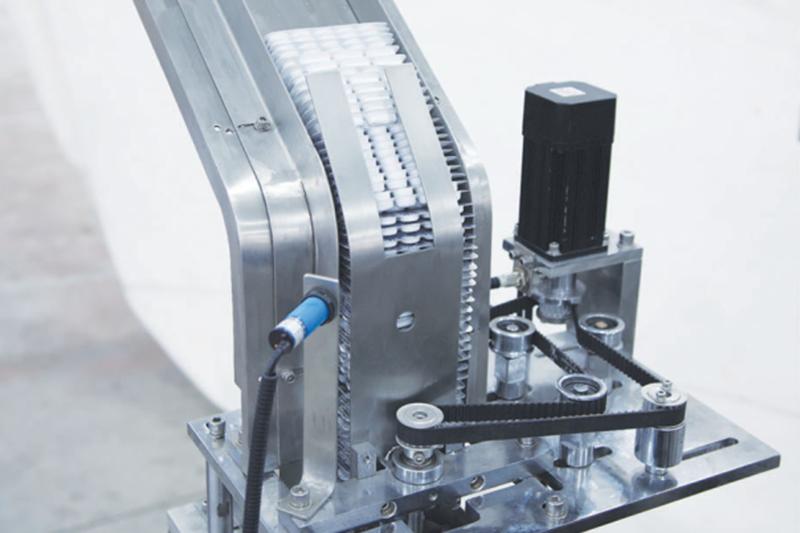

Product Feeding

Blister cartoning machines are designed to receive blister packs containing products like tablets, capsules, or other items. These blister packs are usually loaded onto a conveyor system for further processing.

Box Magazine System

The box magazine mechanism in a cartoning machine plays a vital role by housing a specific number of carton blanks, providing a continuous supply to the packaging station. This component is designed for adaptability, allowing for adjustments to accommodate various carton sizes and styles, and may also include sensors to monitor carton blank levels and reload mechanisms for uninterrupted packaging operations.

Product Pusher

The product pusher mechanism in a cartoning machine, an integral component of the packaging process, stands out for its ability to delicately and precisely transfer a wide range of products into cartons. This adaptable mechanism incorporates precise timing control and safety features, ensuring not only accurate and gentle product placement but also reliability and protection against potential operational issues

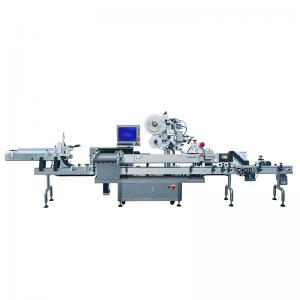

Related Products

Machine Features

China Automatic Blister Cartoning Machine Factory

A blister cartoning machine is a specialized piece of equipment used in the pharmaceutical, food, and other industries for the automated packaging of products stored in blister packs into cartons or boxes.

They automate various packaging processes, including blister feeding, leaflet insertion, carton forming, and sealing. This reduces the need for human intervention and minimizes the risk of operator errors.

Our cartoning machines automate the packaging process, significantly increasing the speed and efficiency of blister-to-box packaging.

Blister cartoning machines can handle various blister pack sizes and shapes, making them suitable for different products.

Automatic packing machines have built-in quality control mechanisms to detect missing blisters, ensuring that only correctly packaged products are released.

This machines can be seamlessly integrated into existing production lines, connecting with other packaging and filling equipment for a streamlined manufacturing process