Round Bottle Wrap Around Labeling Machine Manufacturer

Model: Y-400

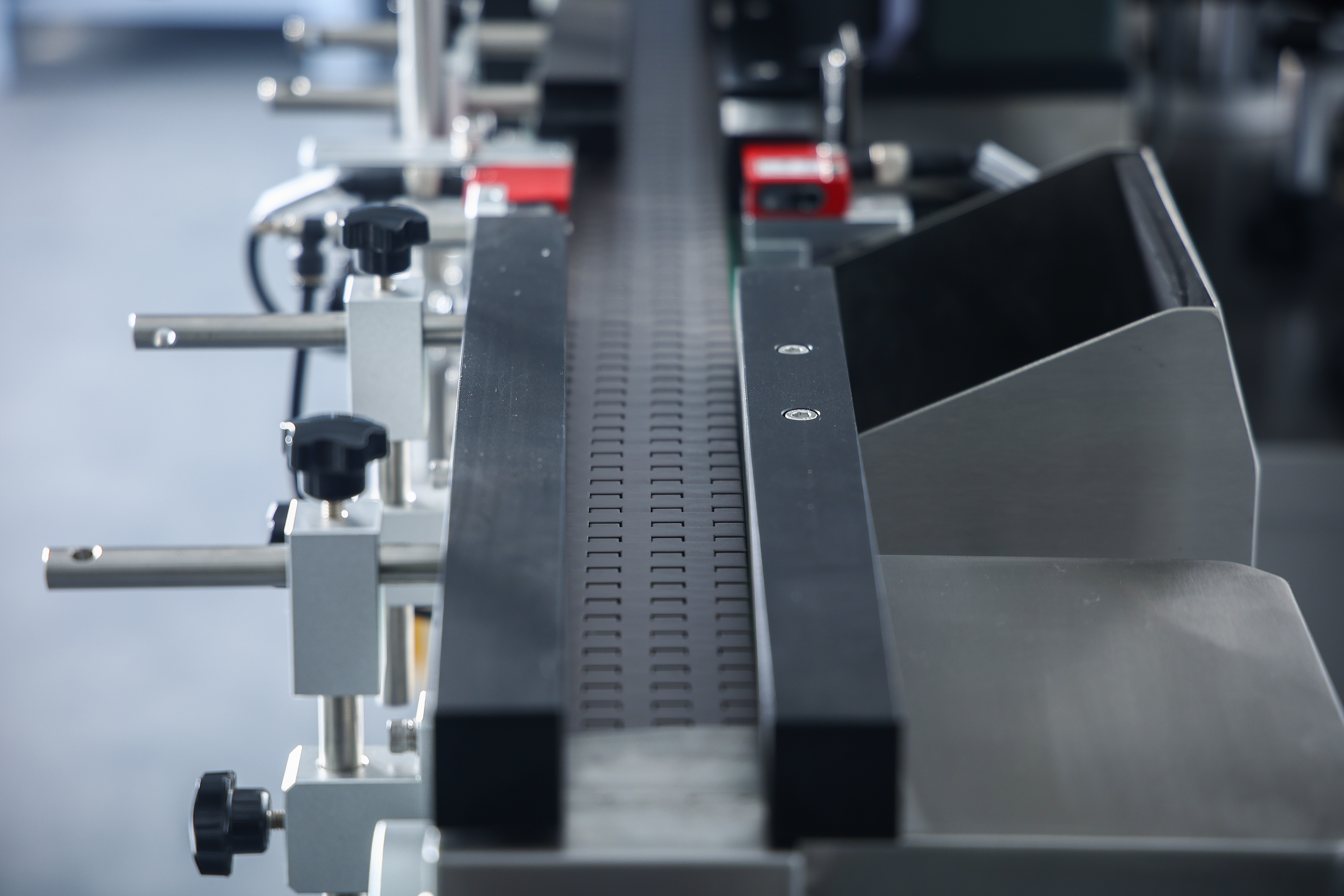

The wrap-around round bottle labeling machine is designed for in-line labeling of small cylindrical bottles at a speed of up to 350 pcs/min. It is ideal for high-speed labeling of round bottles, employing a rubber wheel separation mechanism to achieve precise bottle separation and accommodate varying spacing for labeling

- Speed:up to 350pcs/min

- Application Bottle:10-70mm

- Applicable Label Length:25-350mm

- Applicable label material:Paper labels and transparent labels

- Technical Parameter

- Electrical Parameter

- Application Samples

| Machine Parameters | |

| Applicable bottle diameter | 10-70mm |

| Applicable label material | Paper labels and transparent labels |

| Labeling speed | 0-350 bottles /min |

| Labeling accuracy | ±1mm ( except packaging material error ) |

| Product broken rate | < 0.01 % |

| Label breakage rate | < 0.1 % |

| Labeling pass rate | > 99.9% |

| Power supply | 3.5KW, AC220V, 50HZ |

| Wire Specifications | >1.5mm² |

| Machine dimension | 2716*1333*1650mm |

| Total weight (approximately) | Around 350Kg |

| Noise | <75dB ( one meter away from the equipment ) |

| Applicable inner diameter of the label roll | φ76mm |

| Maximum Label Roll Outer Diameter | Φ400mm |

| Self-adhesive label parameters | |

| Label spacing | 2-4 mm |

| Top/bottom margins on liner | 2 mm |

| Grammage | >62 g/m2 |

| Thickness | >55 μm |

| Tensile strength | Machine Direction : 16kg/25mm ,Cross direction: 7kg/25mm |

| Breaking strength | Machine Direction : 25g/sheet ,Cross direction: 31g/sheet |

| Transparency | 0.52 |

| Electronic control system | ||

| PLC | S7-200 smart | SIEMENS (Germany) |

| Power Supplier | LRS-100-24 ( DC24V/100W) | MEAN WELL (Taiwan) |

| Air switch | ic65N-c16A | Schneider (France) |

| Air switch | ic65N-c10A | Schneider (France) |

| Relay | MY2N- GS | OMRON (Japan) |

| Chassis unit | ||

| Main material | Stainless steel SUS304 | |

| Chassis dimension | 2005(L)×605(W)×672(H) mm | |

| Case structure material | Stainless steel square tube SUS304 | |

| Outer sealing material | Stainless steel SUS304 | |

| Conveyor mechanism | ||

| Main material | Stainless steel SUS304, aluminum A6061, plastic steel chain plate, POM | |

| Conveying motor and reducer |

T1A71B4

B14 0.37KW MU40 30/1 |

SITI (Italy) |

| Conveyor Motor Inverter | FC - 051 0.37 KW | Danfoss (Denmark) |

| Labeling host head | ||

| Main material | Stainless steel SUS304, Aluminum A6061, POM | |

| Label Feeding Motor | 4RK25GN-CT | TWT (Taiwan) |

| Label Feeding speed reducer | 4GN9K | TWT (Taiwan) |

| The bottom paper collecting motor | 4RK25GN-CT | TWT (Taiwan) |

| The bottom paper reducer | 4GN9K | TWT (Taiwan) |

| Label pulling servo motor | SGM7A-08AFA61 | YASKAWA (Japan) |

| Label pulling servo drive | SGD7S-5R5A00B202 | YASKAWA (Japan) |

| Label stock sensor | GTE6-N1211 | SICK (Germany) |

| Label feeding sensor | GL6-N1111 | SICK (Germany) |

| Label detection sensor | WF2-40B410 | SICK (Germany) |

| Wheel attached agency | ||

| Agency main material | Stainless steel SUS304, A6061 aluminum | |

| Wheel attached to the motor | 5IK60GN-YFT | TWT (Taiwan) |

| Wheel attached to the reducer | 5GN9K | TWT (Taiwan) |

| Work content photoelectric detection | FS-N18N | KEYENCE (Japan) |

| HMI | ||

| Main material | Stainless steel SUS304, aluminum A6061 | |

| Touch screen | PFXGP4402W | Proface (Japan) |

| Illuminated button ( green ) | NLB22-F10GA | NHD(Taiwan) |

| Illuminated button ( yellow ) | NLB22-F10GA | NHD(Taiwan) |

| Illuminated button ( red ) | NLB22-F10GA | NHD(Taiwan) |

| Emergency Button | XB2BS542C+ ZB2-BS54C | Schneider (France) |

| Rotary Switches | NLS22-S210RA | Schneider (France) |

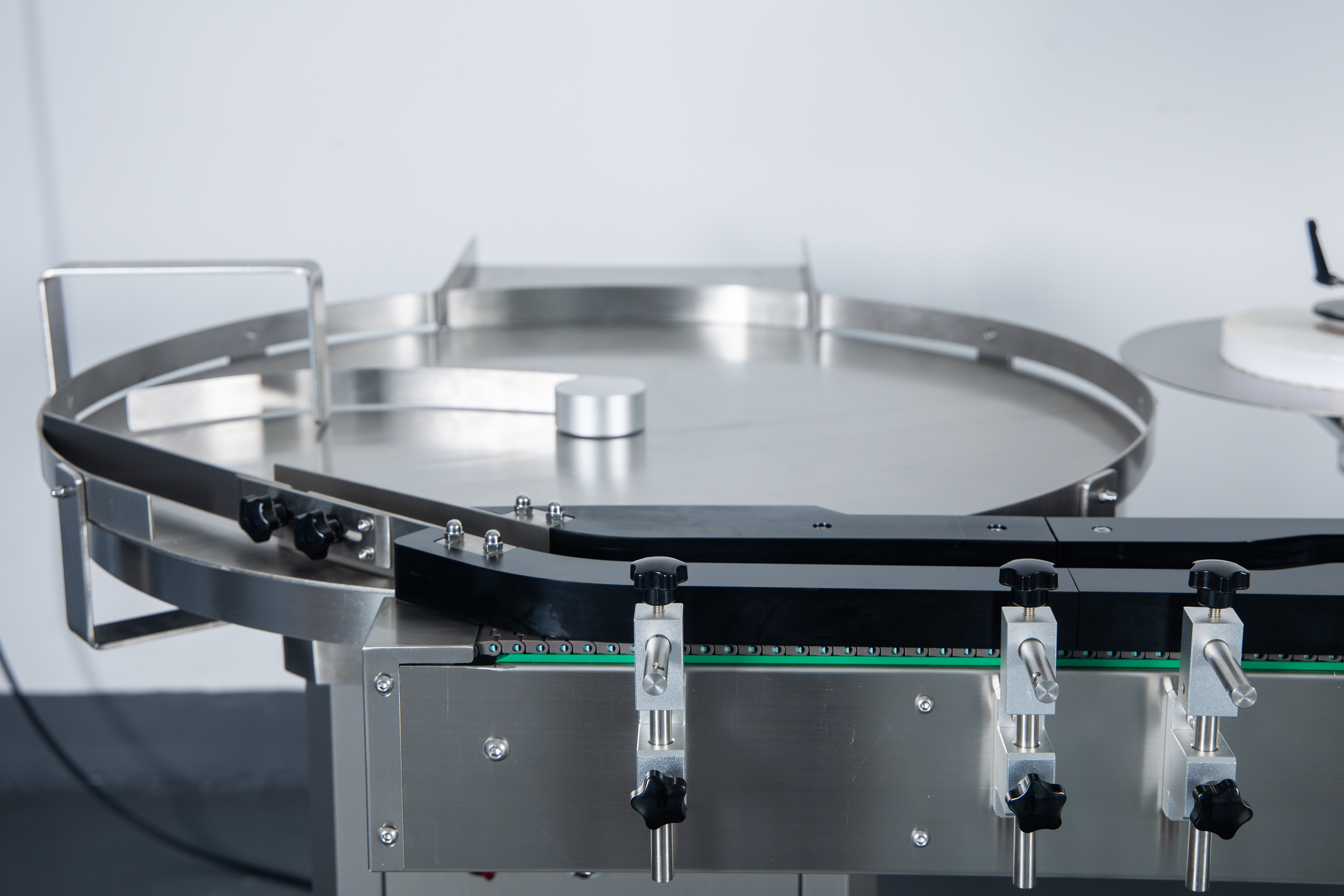

Bottle Unscrambler

This automated bottle unscrambling machine is meticulously designed to enhance the efficiency of bottle preparation for labeling within a production line. 1)Table use SUS304 material, the surface is smooth and smooth, the product rotates with the rotary table

2)Table speed regulating knob:the running speed of the turntable can be changed by adjusting the knob

3)Table knob switch turn on/off discharging turntable operation

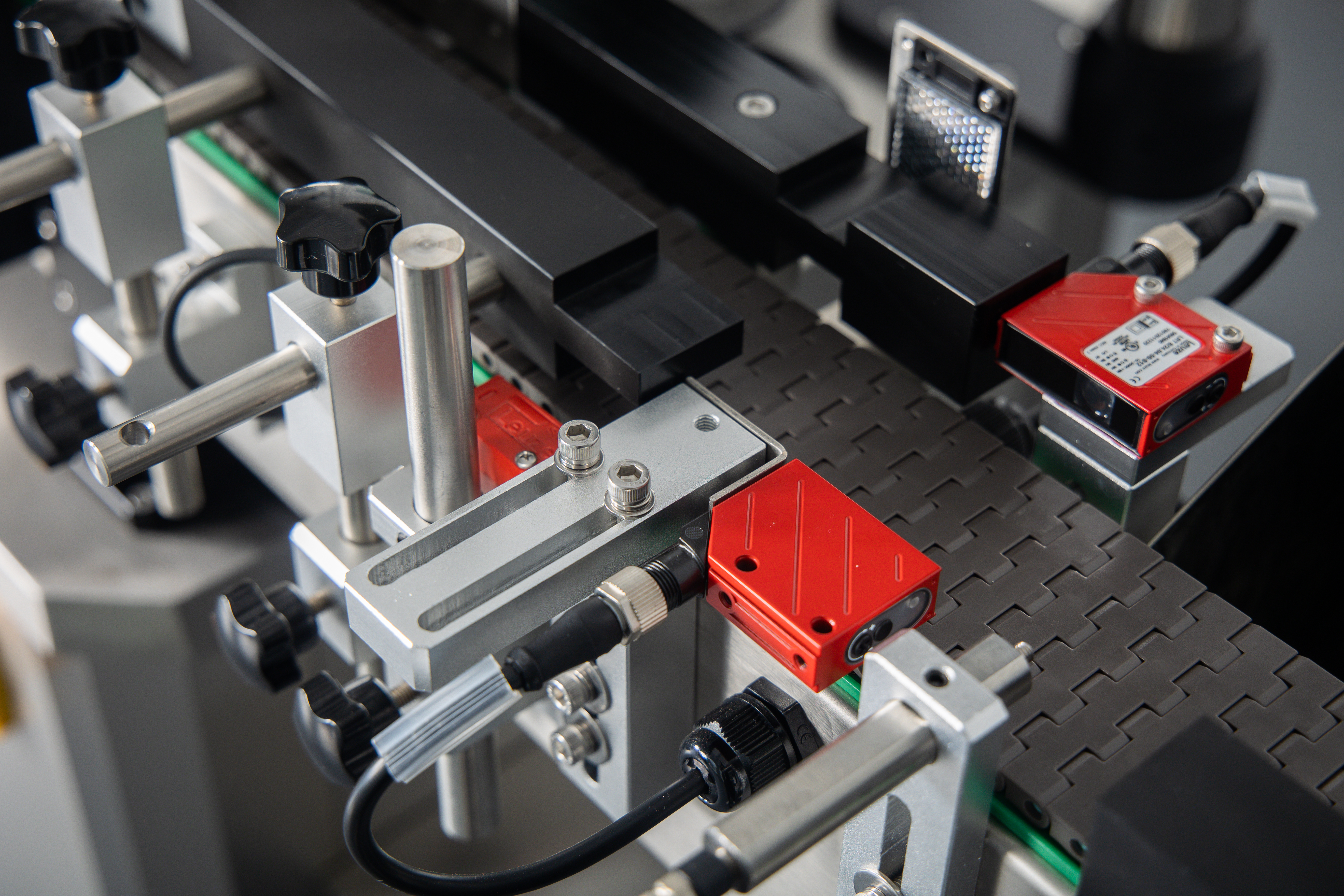

Missing Labeling Detection Mechanism

1)Missing labeling detection photoelectric sensor Detect if there’s any label on bottle body

2)Missing labeling detection photoelectric sensor rack Fix the photoelectric sensor and available for position adjustment

Rejection Confirmation Mechanism

Installed on the reject bin to detect unrejected disqualified products. After the reject mechanism executes the rejection action, the reject confirmation photoelectric sensor confirms whether the rejection is successful. If the rejection fails, the equipment will alarm and shut down.

Related Products

Machine Features

China Round Bottle Wrap Around Labeling Machine Manufacturer

The high-speed pharmaceutical labeling machine, designed for small round bottles, is well-suited for various types of bottles and vials, including Cillin bottles and ampoules, with diameters ranging from 10mm to 70mm. Operating at speeds of up to 350 bottles per minute, this advanced equipment ensures efficient and precise labeling for a diverse range of pharmaceutical containers in the specified size range

Applicable to various types of bottles and vials, including cillin bottles and ampoules, with diameters ranging from 10mm to 70mm.

Capable of achieving speeds of up to 350 bottles per minute, ensuring a rapid and efficient labeling process for high-volume pharmaceutical production lines.

The operation direction of the equipment is the left type, that is, the material is fed from the left and the material is discharged from the right. The equipment can be used as a stand-alone machine, or it can be connected and linked with other equipment in the production line.

The equipment is controlled by Siemens PLC and touch screen. The main electrical components are all internationally renowned brands to ensure the stability of equipment operation and the convenience of maintenance. Wires and electrical components can withstand the corrosion of ozone, alcohol, glutaraldehyde, peracetic acid, hydrogen peroxide, formaldehyde and other disinfectants that meet regulatory requirements for a long time.

Utilizes advanced technology to deliver precise and accurate labeling on small-sized cylindrical containers, meeting the stringent requirements of the pharmaceutical industry.