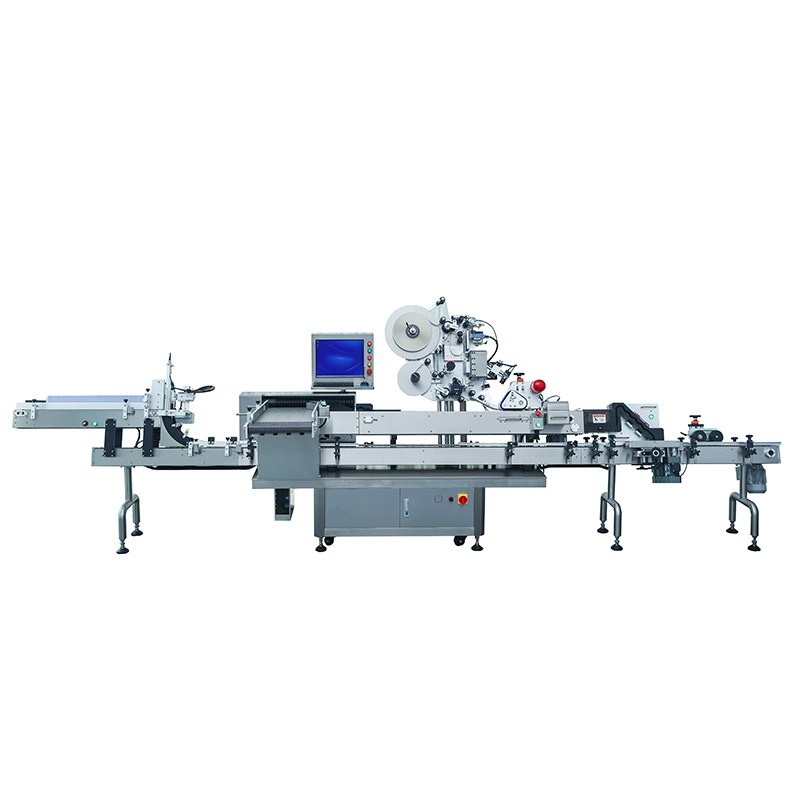

High Speed Horizontal Ampoules Labeling and Tray inserting Machine

Model: Y-510

Automatic feeding,labeling the bottles,automatically arranging the bottles in trays,and with missing label detection.

- Speed:up to 300pcs/min

- Application Bottle Diameter:10-30mm

- Tray inserting capacity:30-90 trays/min

- Applicable label material:Paper labels and transparent labels

- Technical Parameter

- Electrical Parameter

- Application Samples

| Tray Inserting System Parameters | |

| Applicable Products | 1-20ml ampoules,5pcs/tray or 10pcs/tray |

| Applicable tray size | Length:50-150mm,Width:60-120mm |

| Tray inserting capacity | 30~90trays/min |

| Airsource | 0.4MPa |

| Air Consumption | 300 L/min(90 trays/min) |

| Power | 0.4kw |

| Request of PVC trays |

1.The edges of the plastic tray need to be neat

and uniform in size. 2.The width dimensions of the edges of the plastic tray should be 3.5mm at least. 3.The thickness of the plastic tray should be large than 0.30mm. |

| Labeling System Parameters | |

| Applicable product size | 10-30mm |

| Applicable label material | Paper labels and transparent labels |

| Labeling speed | 0-500 bottles /min |

| Labeling accuracy | ±1mm ( except packaging material error ) |

| Length of label | 25-95mm |

| Product broken rate | < 0.01 % |

| Label breakage rate | < 0.1 % |

| Labeling pass rate | > 99.9% |

| Power supply | 2.5KW, AC220V, 50HZ |

| Wire Specifications | >1.5mm² |

| Total weight (approximately) | Around 380Kg |

| Noise | <75dB ( one meter away from the equipment ) |

| Applicable inner diameter of the label roll | φ76mm |

| Maximum Label Roll Outer Diameter | Φ300mm |

| Self-adhesive label parameters | |

| Label spacing | 2-4 mm |

| Top/bottom margins on liner | 2 mm |

| Grammage | >62 g/m2 |

| Thickness | >55 μm |

| Tensile strength | Machine Direction : 16kg/25mm ,Cross direction: 7kg/25mm |

| Breaking strength | Machine Direction : 25g/sheet ,Cross direction: 31g/sheet |

| Transparency | 0.52 |

| Electronic control system | ||

| PLC | S7-200 smart | SIEMENS (Germany) |

| Power Supplier | LRS-100-24 ( DC24V/100W) | MEAN WELL (Taiwan) |

| Air switch | ic65N-c16A | Schneider (France) |

| Air switch | ic65N-c10A | Schneider (France) |

| Relay | MY2N- GS | OMRON (Japan) |

| Chassis unit | ||

| Main material | Stainless steel SUS304 | |

| Chassis dimension | 2005(L)×605(W)×672(H) mm | |

| Case structure material | Stainless steel square tube SUS304 | |

| Outer sealing material | Stainless steel SUS304 | |

| Conveyor mechanism | ||

| Main material | Stainless steel SUS304, aluminum A6061, plastic steel chain plate, POM | |

| Conveying motor and reducer |

T1A71B4

B14 0.37KW MU40 30/1 |

SITI (Italy) |

| Conveyor Motor Inverter | FC - 051 0.37 KW | Danfoss (Denmark) |

| Labeling host head | ||

| Main material | Stainless steel SUS304, Aluminum A6061, POM | |

| Label Feeding Motor | 4RK25GN-CT | TWT (Taiwan) |

| Label Feeding speed reducer | 4GN9K | TWT (Taiwan) |

| The bottom paper collecting motor | 4RK25GN-CT | TWT (Taiwan) |

| The bottom paper reducer | 4GN9K | TWT (Taiwan) |

| Label pulling servo motor | SGM7A-08AFA61 | YASKAWA (Japan) |

| Label pulling servo drive | SGD7S-5R5A00B202 | YASKAWA (Japan) |

| Label stock sensor | GTE6-N1211 | SICK (Germany) |

| Label feeding sensor | GL6-N1111 | SICK (Germany) |

| Label detection sensor | WF2-40B410 | SICK (Germany) |

| Wheel attached agency | ||

| Agency main material | Stainless steel SUS304, A6061 aluminum | |

| Wheel attached to the motor | 5IK60GN-YFT | TWT (Taiwan) |

| Wheel attached to the reducer | 5GN9K | TWT (Taiwan) |

| Work content photoelectric detection | FS-N18N | KEYENCE (Japan) |

| HMI | ||

| Main material | Stainless steel SUS304, aluminum A6061 | |

| Touch screen | PFXGP4402W | Proface (Japan) |

| Illuminated button ( green ) | NLB22-F10GA | NHD(Taiwan) |

| Illuminated button ( yellow ) | NLB22-F10GA | NHD(Taiwan) |

| Illuminated button ( red ) | NLB22-F10GA | NHD(Taiwan) |

| Emergency Button | XB2BS542C+ ZB2-BS54C | Schneider (France) |

| Rotary Switches | NLS22-S210RA | Schneider (France) |

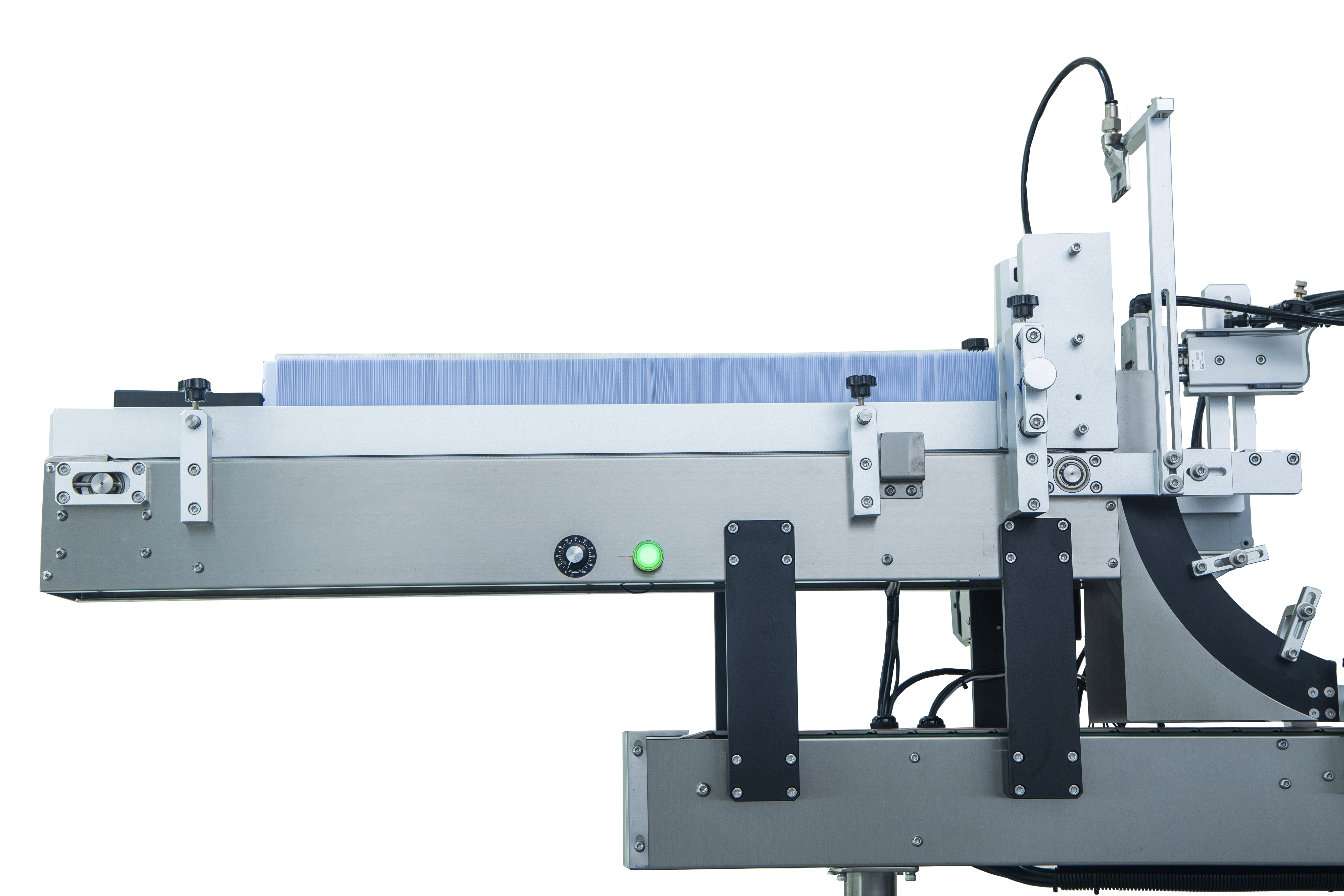

Small Bottle Feeding mechanism

Buffer and conveying products to be labeled.

1)Conveyor motor: Offer power to conveyor line

2)Object photoelectric sensor: When the product is detected, output labeling signal

3)Roller: Products placed in the middle of two rollers, when reaching to “wheel attachment unit”, will rotate accordingly

4)Adjustment seat:Adjust the conveyor belt tension

Tray Separating and Feeding mechanism

Suitable for small round bottles such as ampoule bottles and vial bottles, this machine features precise PVC tray feeding controlled by a stable servo system.

Tray Inserting System

Tray Inserting System to insert the labelled vial or small bottle into the blister trays to connect with automatic cartoning machine.

Related Products

Machine Features

China High Speed Horizontal Labeling and Tray inserting Machine

Designed for horizontal labeling on various small round bottles with low bottle breakage rates (as low as one in two hundred thousand), this machine utilizes a screw bottle separation mechanism synchronized with the conveyor belt, ensuring no bottle shortages or breakage. Equipped with high-quality imported servo motors for fast label dispensing and high precision, it offers efficient and precise labeling with an accuracy of ±0.5mm.

Compared to other manufacturers' vertical feeding systems, our horizontal feeding system is not only safer and more convenient but also significantly reduces the bottle breakage rate to one in two hundred thousand, which is more than ten times lower than that of other manufacturers. Equipped with a bottle shortage detection device, it can automatically decelerate when the number of bottles falls below a certain threshold, and it can accelerate automatically after reloading, greatly reducing manual labor intensity.

Using a screw bottle-separation mechanism synchronized with the conveyor belt machinery ensures that containers smoothly enter the conveyor without bottle overturns or breakage.

The operation direction of the equipment is the left type, that is, the material is fed from the left and the material is discharged from the right. The equipment can be used as a stand-alone machine, or it can be connected and linked with other equipment in the production line.

The equipment is controlled by Siemens PLC and touch screen. The main electrical components are all internationally renowned brands to ensure the stability of equipment operation and the convenience of maintenance. Wires and electrical components can withstand the corrosion of ozone, alcohol, glutaraldehyde, peracetic acid, hydrogen peroxide, formaldehyde and other disinfectants that meet regulatory requirements for a long time.

The equipment has the protection functions of shortage of labels and material shortage, alarm and linkage shutdown protection.