Multi-Function Single,Double And Three Side High Speed Front & Back Labeling Machine

Model: P-280

It has widely application of products labeling, suitable for single,double and three side labeling request.Can be applied on round, square and flat objects. also application of labels and tamper evident on food boxes or pharm boxes.

- Speed:up to 300pcs/min

- Application Products:Round,Square and Flat Bottles

- Applicable Label Length:30-350mm

- Applicable label material:Paper labels and transparent labels

- Technical Parameter

- Electrical Parameter

- Application Samples

| Machine Parameters | |

| Applicable label material | Paper labels and transparent labels |

| Labeling speed | 0-300 bottles /min |

| Labeling accuracy | ±1mm ( except packaging material error ) |

| Length of label | 25-95mm |

| Product broken rate | < 0.01 % |

| Label breakage rate | < 0.1 % |

| Labeling pass rate | > 99.9% |

| Power supply | 2.5KW, AC220V, 50HZ |

| Wire Specifications | >1.5mm² |

| Total weight (approximately) | Around 380Kg |

| Noise | <75dB ( one meter away from the equipment ) |

| Applicable inner diameter of the label roll | φ76mm |

| Maximum Label Roll Outer Diameter | Φ300mm |

| Self-adhesive label parameters | |

| Label spacing | 2-4 mm |

| Top/bottom margins on liner | 2 mm |

| Grammage | >62 g/m2 |

| Thickness | >55 μm |

| Tensile strength | Machine Direction : 16kg/25mm ,Cross direction: 7kg/25mm |

| Breaking strength | Machine Direction : 25g/sheet ,Cross direction: 31g/sheet |

| Transparency | 0.52 |

| Electronic control system | ||

| PLC | S7-200 smart | SIEMENS (Germany) |

| Power Supplier | LRS-100-24 ( DC24V/100W) | MEAN WELL (Taiwan) |

| Air switch | ic65N-c16A | Schneider (France) |

| Air switch | ic65N-c10A | Schneider (France) |

| Relay | MY2N- GS | OMRON (Japan) |

| Chassis unit | ||

| Main material | Stainless steel SUS304 | |

| Chassis dimension | 2005(L)×605(W)×672(H) mm | |

| Case structure material | Stainless steel square tube SUS304 | |

| Outer sealing material | Stainless steel SUS304 | |

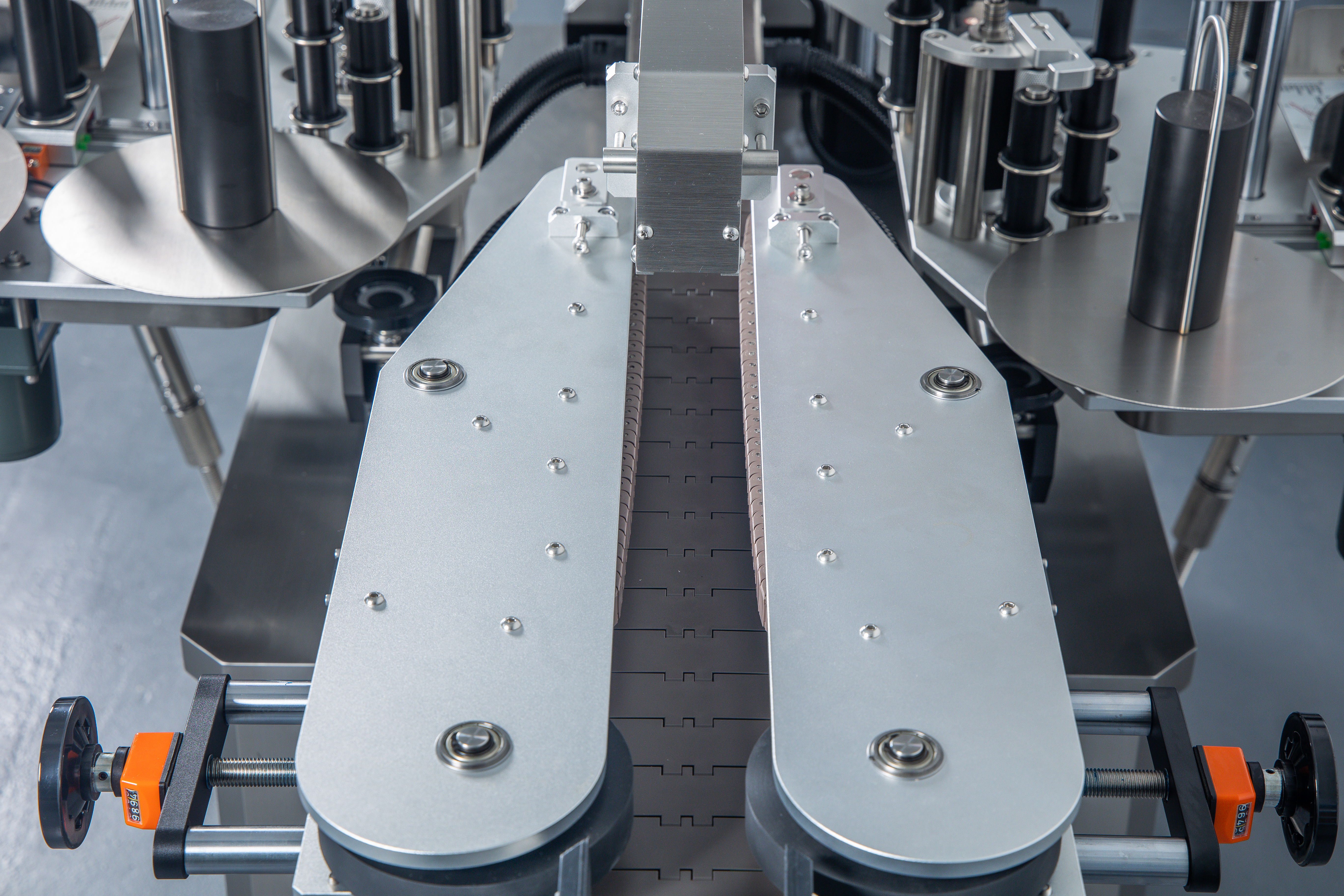

| Conveyor mechanism | ||

| Main material | Stainless steel SUS304, aluminum A6061, plastic steel chain plate, POM | |

| Conveying motor and reducer |

T1A71B4

B14 0.37KW MU40 30/1 |

SITI (Italy) |

| Conveyor Motor Inverter | FC - 051 0.37 KW | Danfoss (Denmark) |

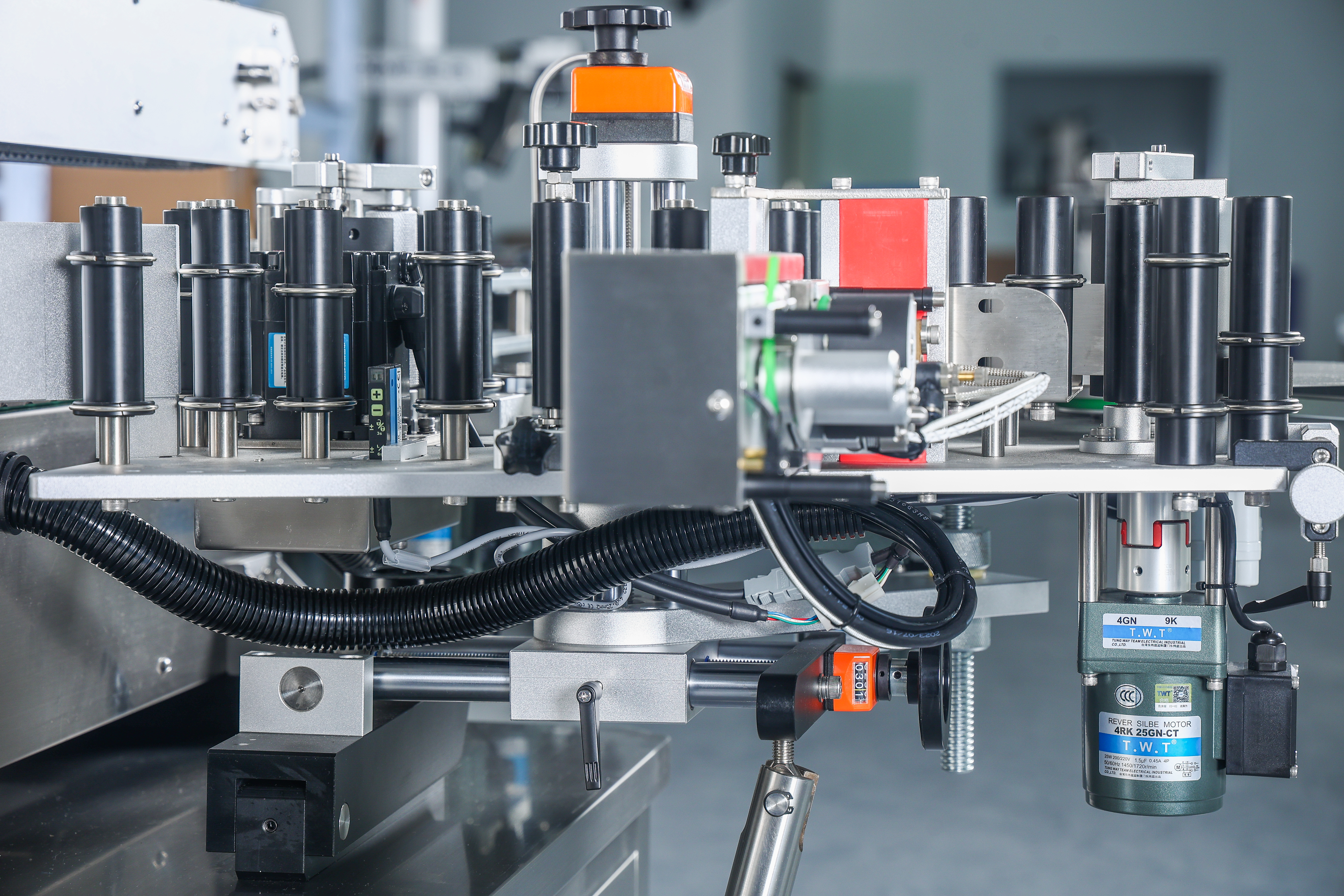

| Labeling host head | ||

| Main material | Stainless steel SUS304, Aluminum A6061, POM | |

| Label Feeding Motor | 4RK25GN-CT | TWT (Taiwan) |

| Label Feeding speed reducer | 4GN9K | TWT (Taiwan) |

| The bottom paper collecting motor | 4RK25GN-CT | TWT (Taiwan) |

| The bottom paper reducer | 4GN9K | TWT (Taiwan) |

| Label pulling servo motor | SGM7A-08AFA61 | YASKAWA (Japan) |

| Label pulling servo drive | SGD7S-5R5A00B202 | YASKAWA (Japan) |

| Label stock sensor | GTE6-N1211 | SICK (Germany) |

| Label feeding sensor | GL6-N1111 | SICK (Germany) |

| Label detection sensor | WF2-40B410 | SICK (Germany) |

| Wheel attached agency | ||

| Agency main material | Stainless steel SUS304, A6061 aluminum | |

| Wheel attached to the motor | 5IK60GN-YFT | TWT (Taiwan) |

| Wheel attached to the reducer | 5GN9K | TWT (Taiwan) |

| Work content photoelectric detection | FS-N18N | KEYENCE (Japan) |

| HMI | ||

| Main material | Stainless steel SUS304, aluminum A6061 | |

| Touch screen | PFXGP4402W | Proface (Japan) |

| Illuminated button ( green ) | NLB22-F10GA | NHD(Taiwan) |

| Illuminated button ( yellow ) | NLB22-F10GA | NHD(Taiwan) |

| Illuminated button ( red ) | NLB22-F10GA | NHD(Taiwan) |

| Emergency Button | XB2BS542C+ ZB2-BS54C | Schneider (France) |

| Rotary Switches | NLS22-S210RA | Schneider (France) |

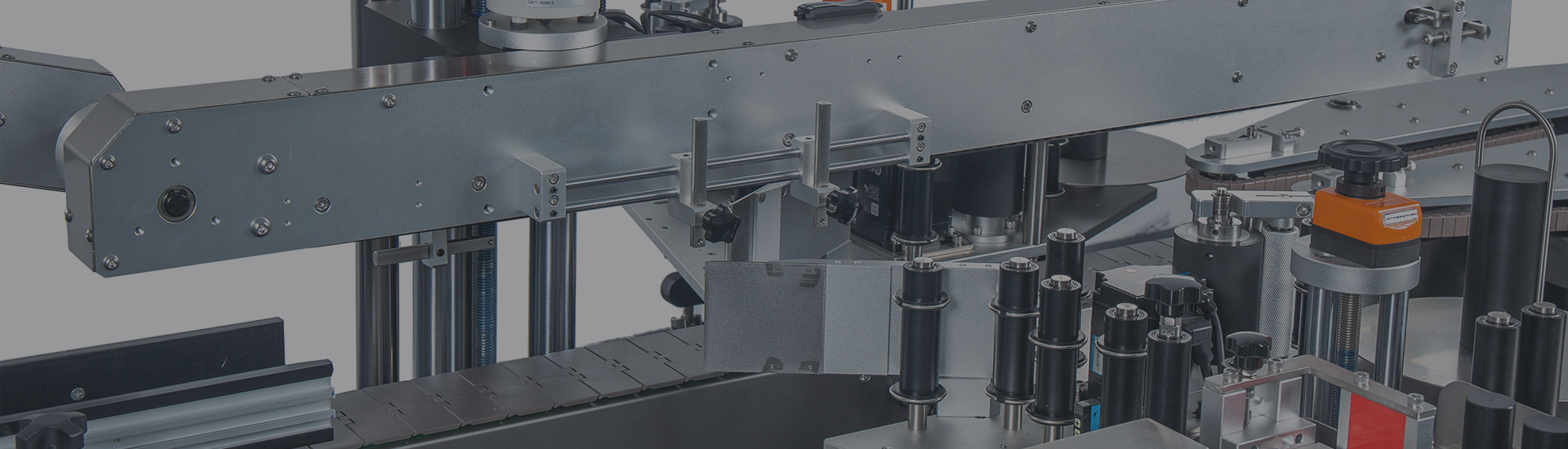

Differential Carton Separating Mechanism

The linear velocity of the differential separator belt has a certain speed difference from the linear velocity of the conveyor belt, so that the cartons can be kept at a certain interval after passing through the mechanism.

1) Front and rear adjustment handwheel, to adjust the front and rear position of the separator.

2) Separator motor, to provide power to the separating belt.

3) Separating belt, to clamp the products for conveying slowly, and separate the products for a certain spacing.

Top Hold-Down Mechanism

1) Tension seat: to adjust the tension of the top hold-down sponge belt.

2) Photoelectric device: to detect products, control label releasing from the labelling host.

3) Top hold-down sponge belt: to attach sponge onto synchronous belt, combining with the conveyor belt to clamp the products.

4) The height adjustable handwheel: to adjust the height of the pressurizing mechanism by rotating the handwheel to fit different specifications of product.

5) The pressurizing motor: tor provide power for top hold-down sponge belt.

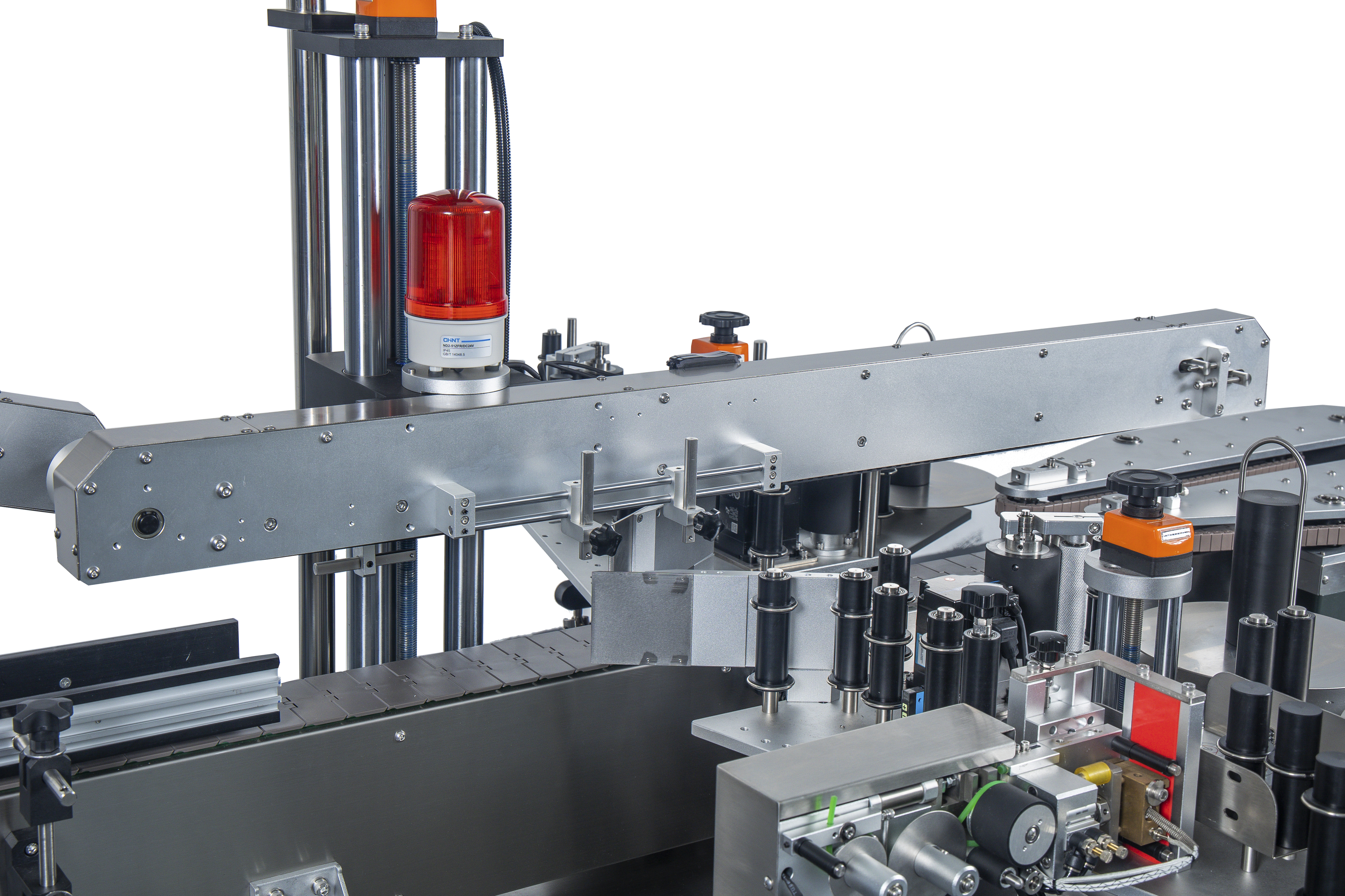

Labelling Host Unit

1) Label detection photoelectric sensor: to detect the gap between labels, send the stop signal when a label is released, and also provide the alarm function for a missing or broken label.

2) Backing paper rewind reel: to rewind label backing paper.

3) Height adjusting handwheel: to adjust the height of the entire labelling host relative to the chassis countertop, thus adjusting the label position relative to the labelling height on the product.

4) Backing paper rewind tension control handwheel: to adjust the tension of the backing paper rewind reel.

5) Label stock photoelectric sensor: to send alarming signal when labels are used up.

6) Label roll unwind reel: where the label roll is loaded.

Related Products

Vertically Cartoning Machine For Washing Powder,Powder Products Feeding Cartoning Machine

Machine Features

China Multi-Function Single Double And Three Side High Speed Front Back Labeling Machine

The machine, capable of simultaneous double-sided circumferential surface labeling, accommodates bottles of various shapes, including round, flat, square, and special-shaped bottles, as well as cartons and boxes. This versatile double side bottle sticker labeling machine is suitable for diverse industries such as cosmetics, food, medicine, daily chemicals, and more.

The cartons are transported to the box-separating and correcting mechanism through the conveyor belt, and enter the upper pressing mechanism after separating the spacing. The head of the labeling machine outputs the label, sticks the self-adhesive label on the carton, and presses the label firmly through the labeling sponge wheel.

When changing the specifications, you only need to simply adjust the guardrail, the replacement is quick and convenient, and the specification replacement can be completed within 30 minutes.

The operation direction of the equipment is the left type, that is, the material is fed from the left and the material is discharged from the right. The equipment can be used as a stand-alone machine, or it can be connected and linked with other equipment in the production line.

The equipment is controlled by Siemens PLC and touch screen. The main electrical components are all internationally renowned brands to ensure the stability of equipment operation and the convenience of maintenance. Wires and electrical components can withstand the corrosion of ozone, alcohol, glutaraldehyde, peracetic acid, hydrogen peroxide, formaldehyde and other disinfectants that meet regulatory requirements for a long time.

The equipment has the protection functions of shortage of labels and material shortage, alarm and linkage shutdown protection.